Perception: an exhibition

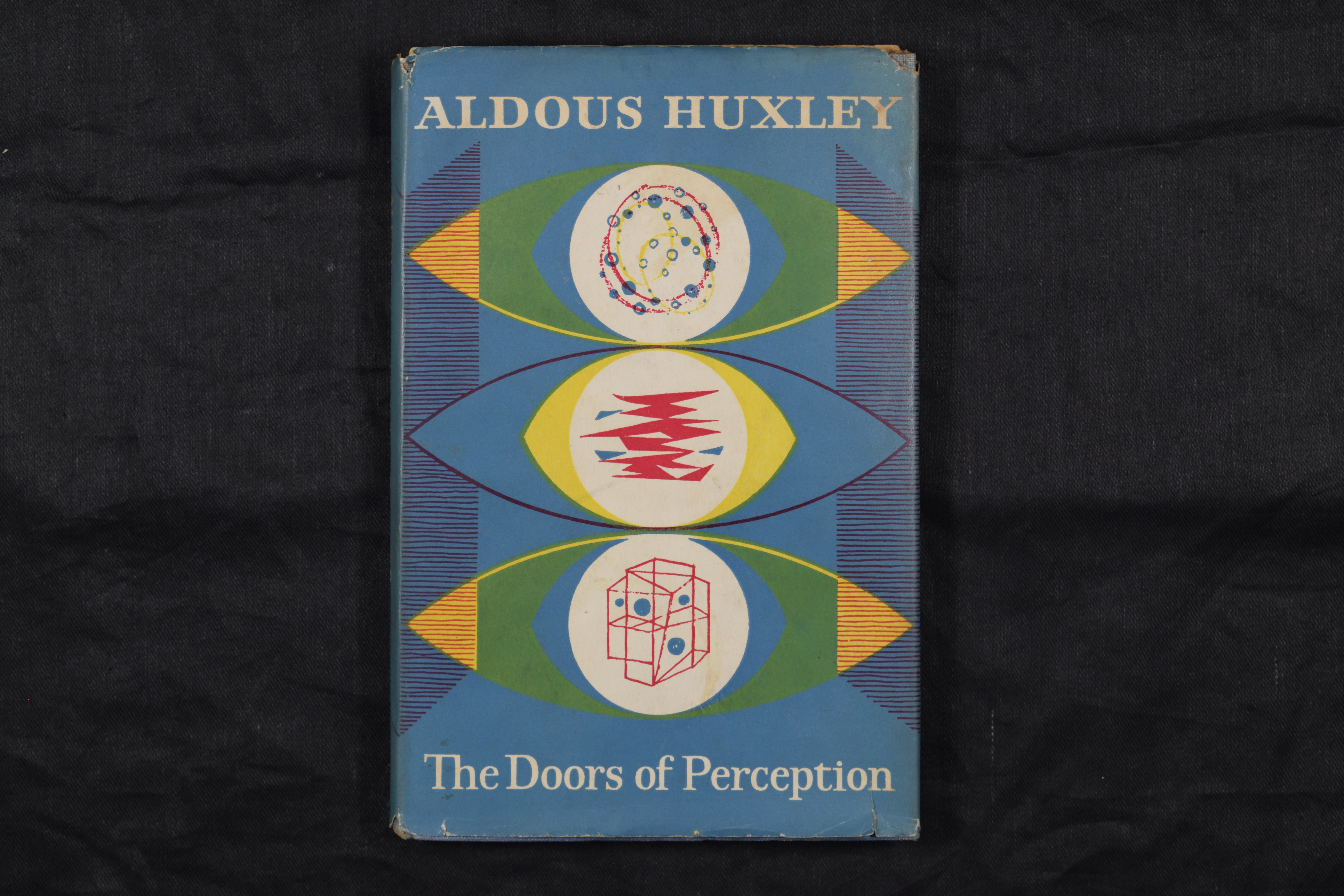

‘From the author’

Joseph Williamson and the establishment of the transatlantic slave trade

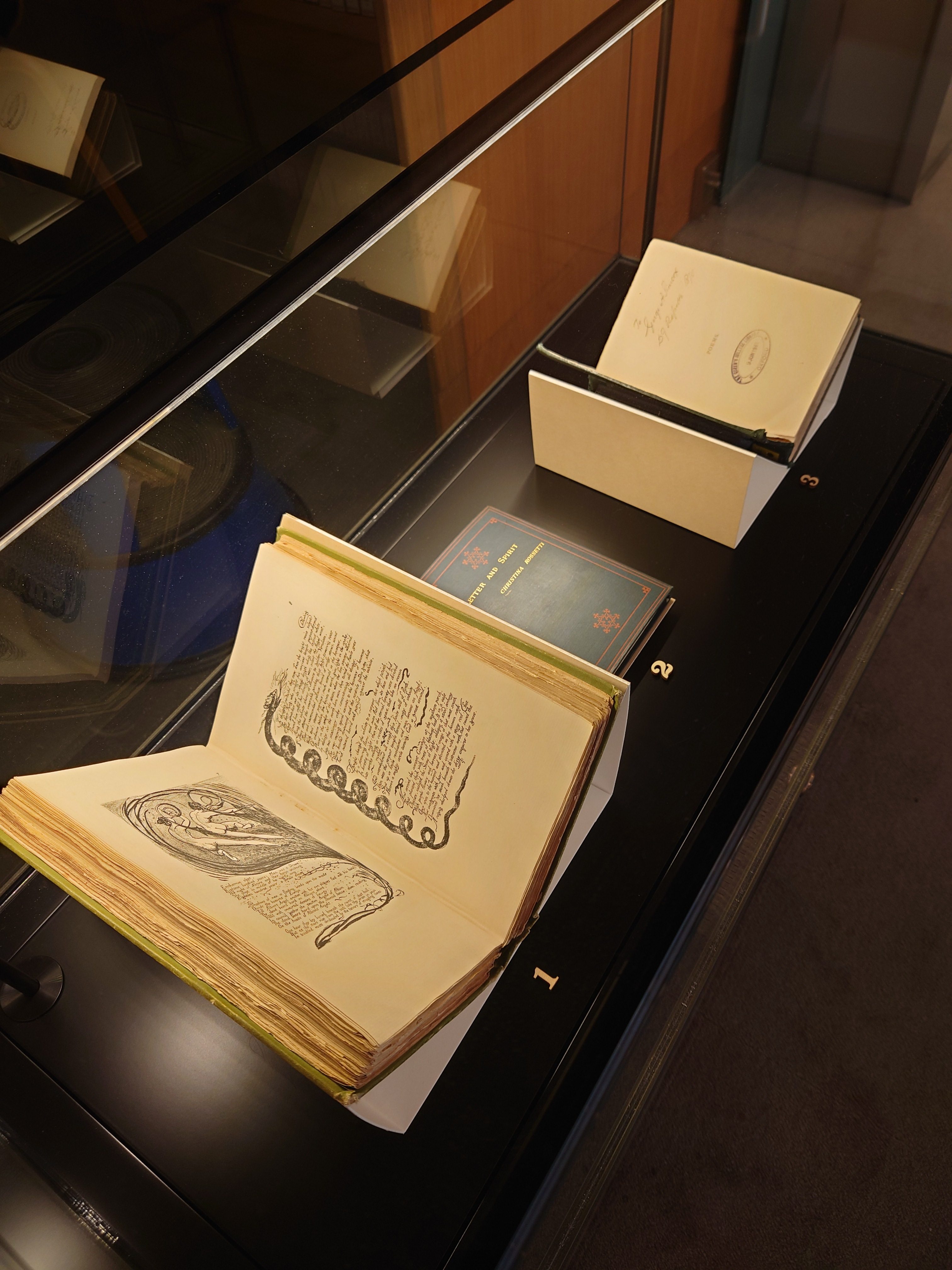

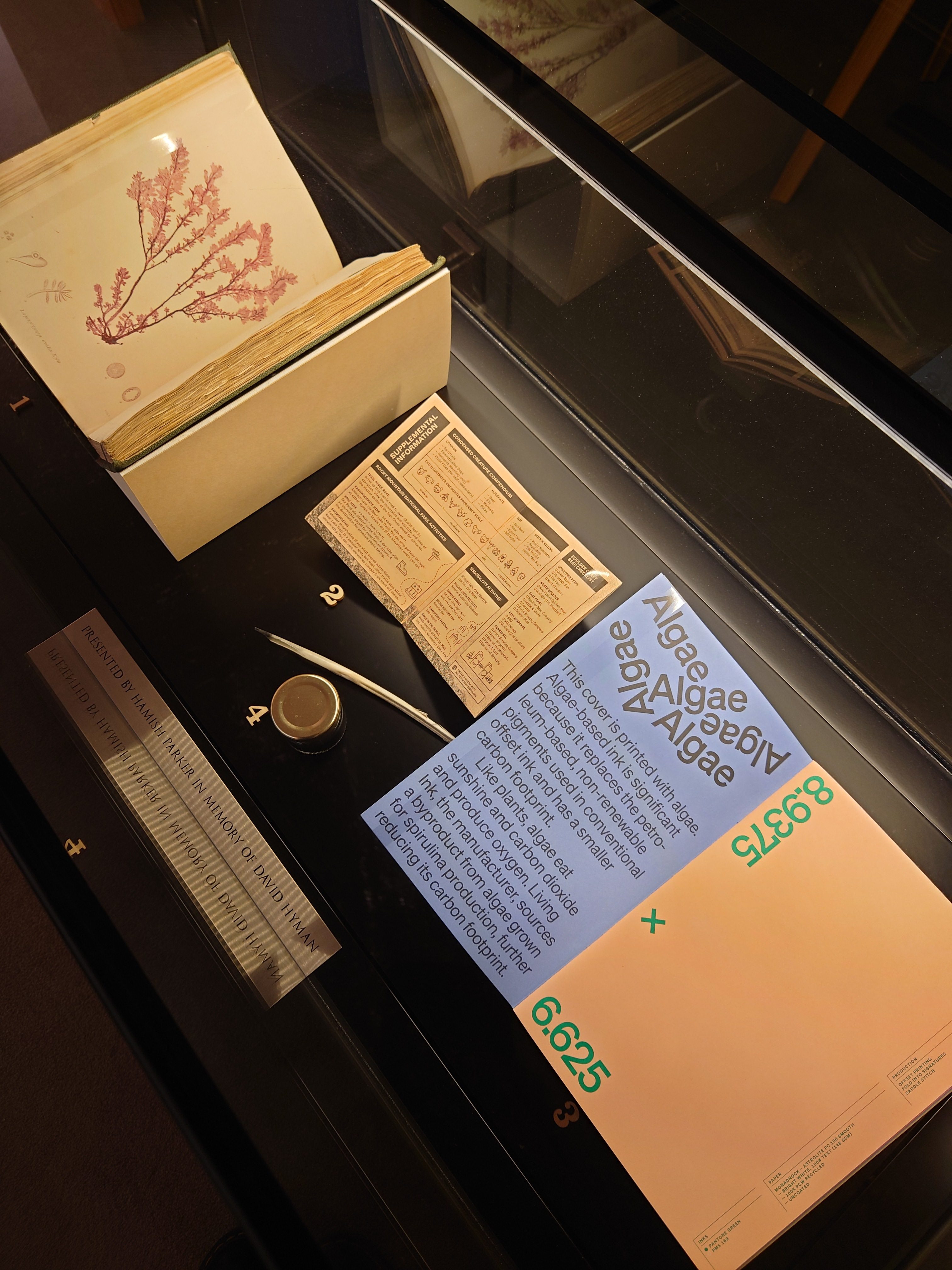

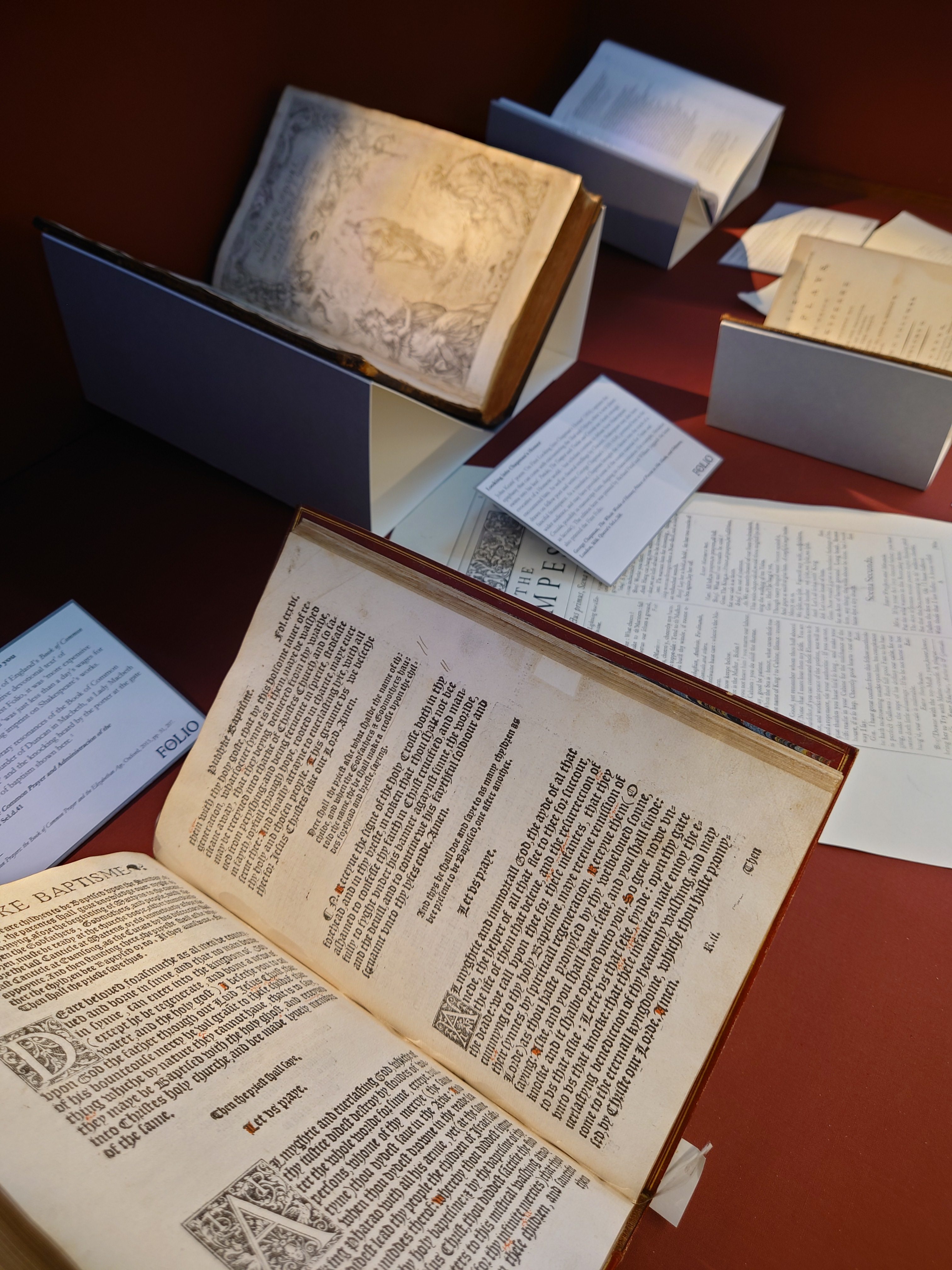

Ink : an exhibition

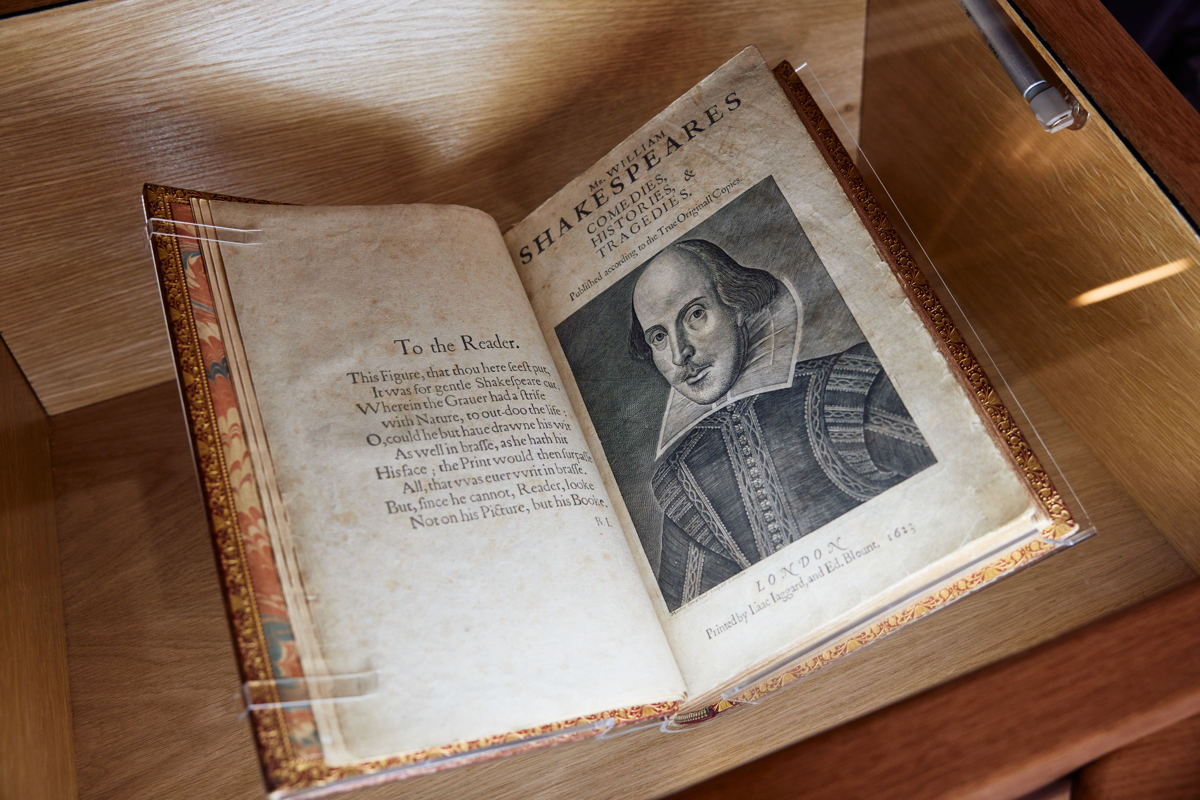

Shakespeare’s Books

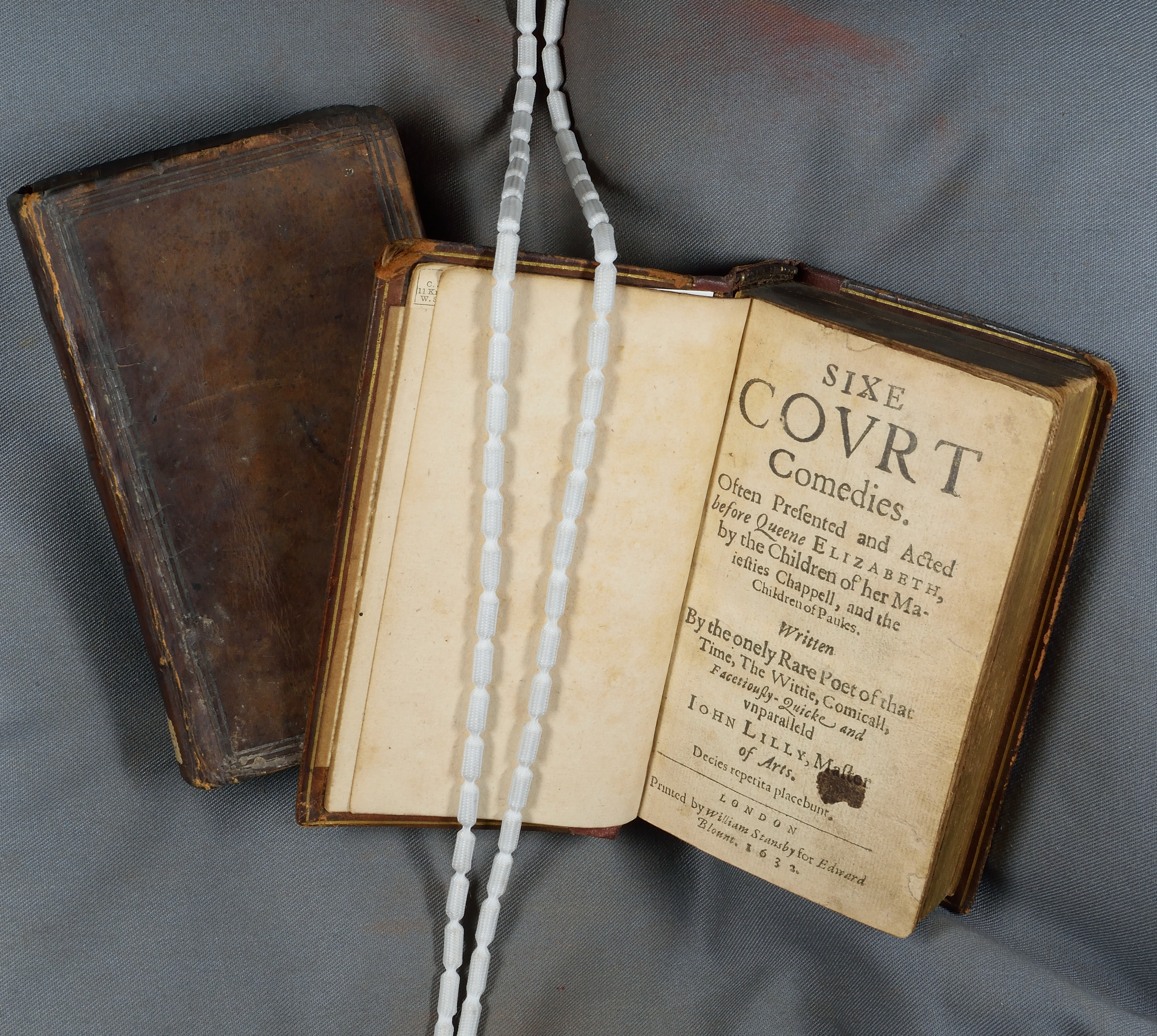

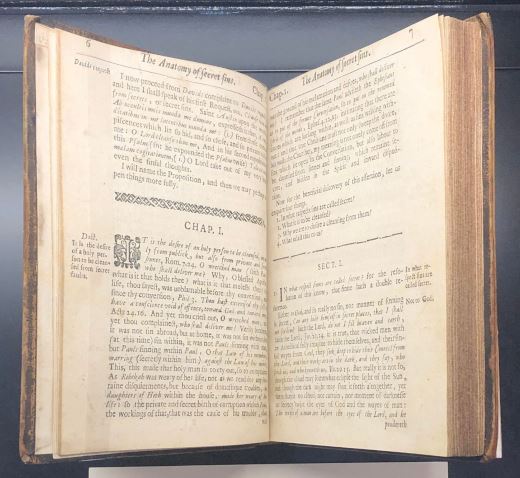

The Bodies of Shakespeare’s Contemporaries

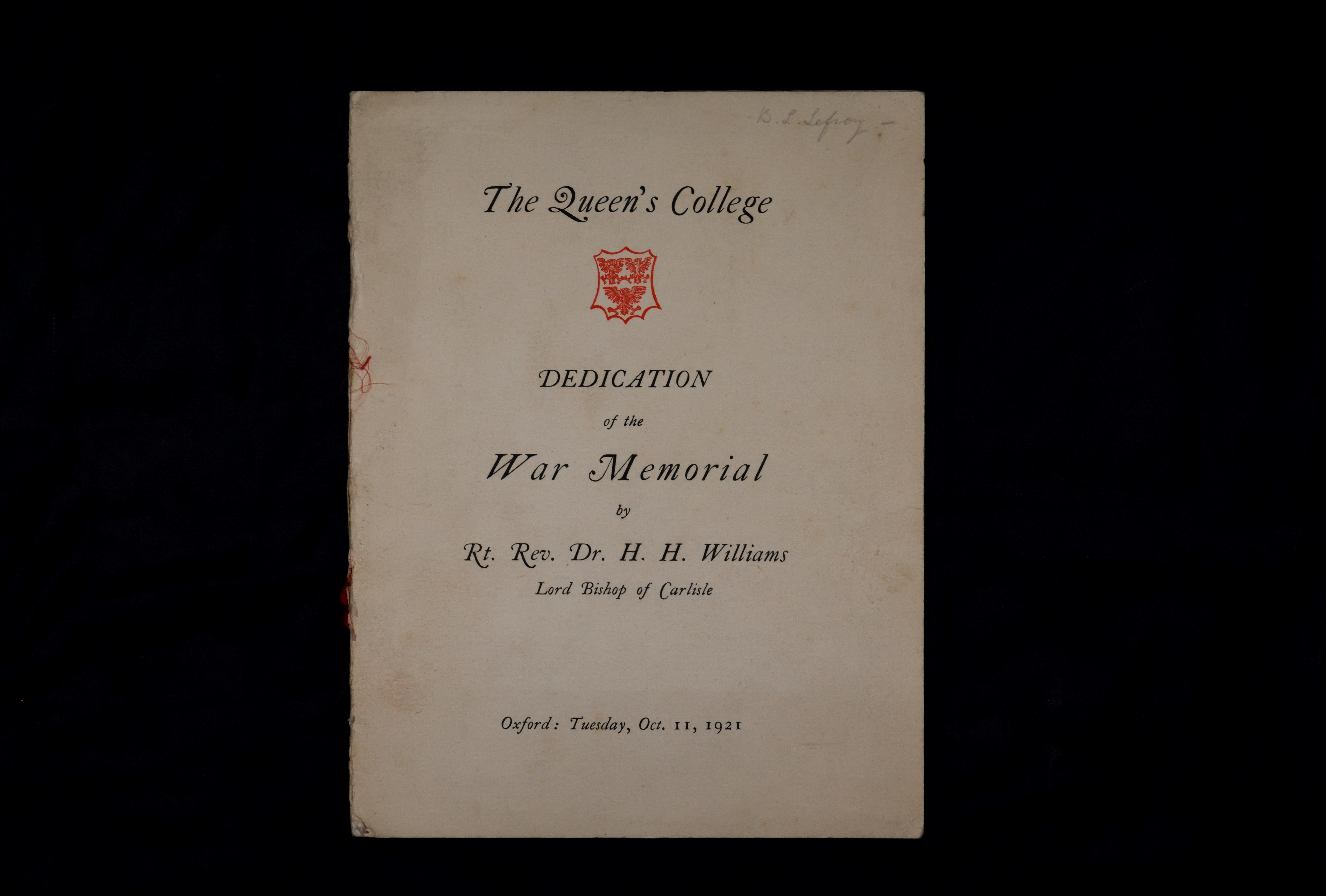

Folio 400 at The Queen’s College

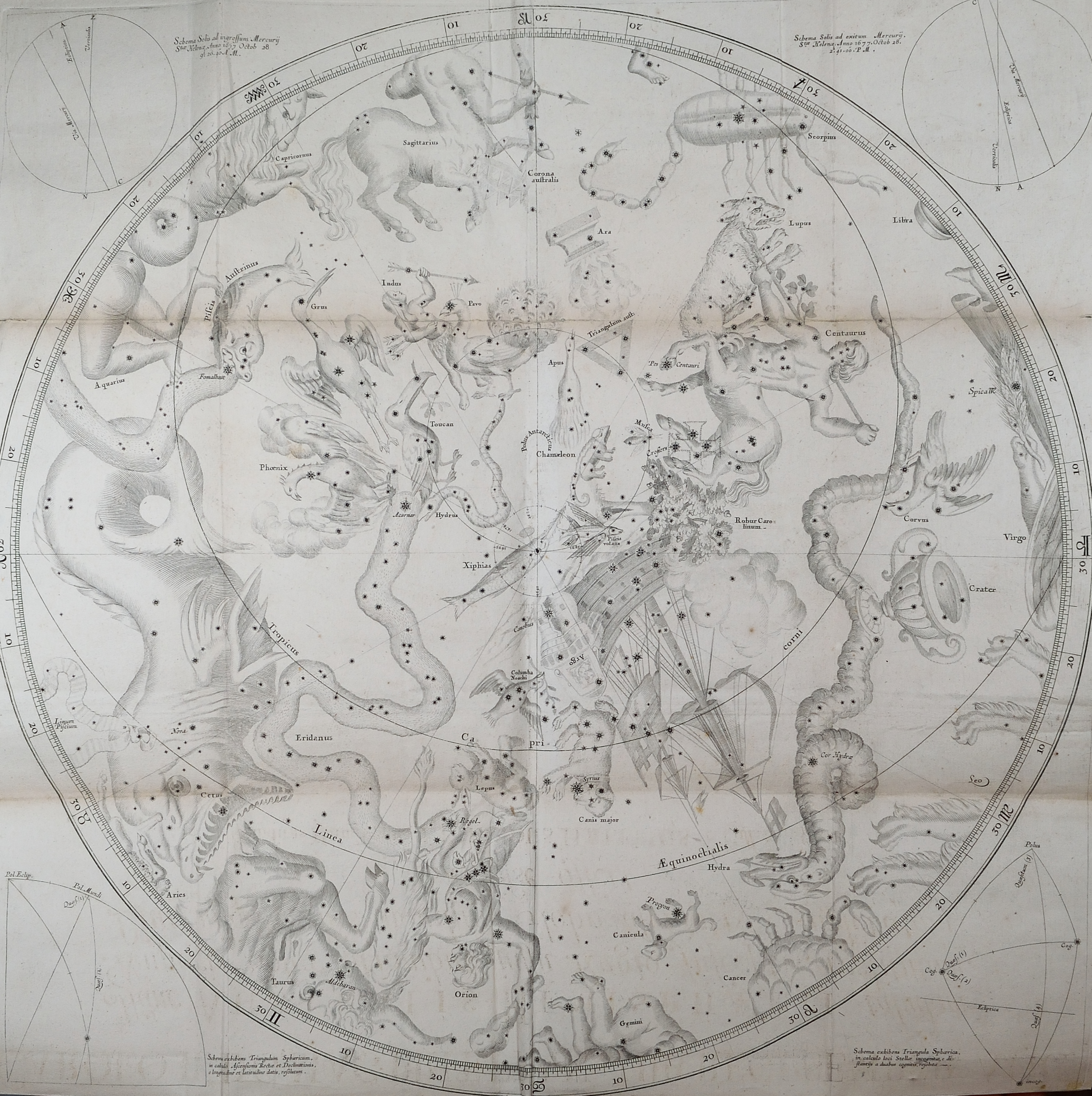

Edmond Halley: In Print

Disease and the body

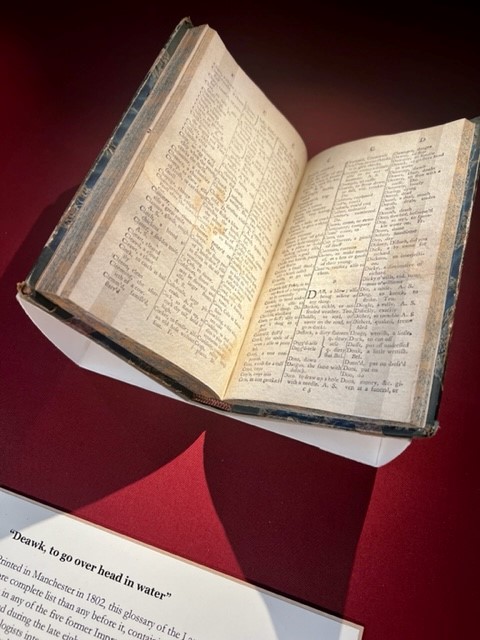

“Cummerland talk”: The Dialects of Cumbria and Lancashire

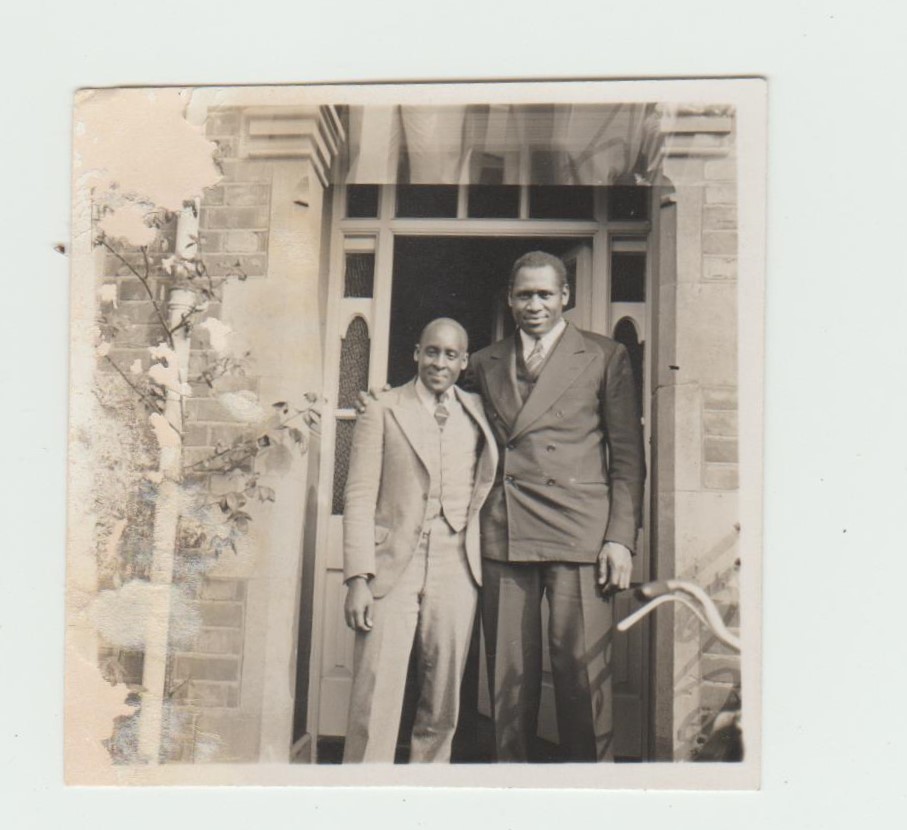

Africa Answers Back